Process Design

Our green processing technologies help save the environment, at the same time produce a looking great product

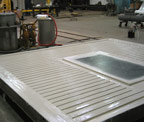

Looks great and it’s environmentally friendly – PDG’s infusion technologies reduce styrene emissions during processing. The application of this laminating technology, provides a wide range of exterior treatments replicating the look of any building material available; wood, brick, or stone. The laminating material is impregnated with a ceramic material, which increases the insulation, durability and burn-resistance factors.

PDG developed exterior wall panels which are made with laminating resins used in tunnel construction and transportation industries due to it's class 1 flame rating, safety and durability. The exterior panel is coated with Polane S Plus which gives a 50 year, low maintenance exterior finish and it can be painted if so desired. All coatings are low VOC.

PDG’s laminating systems reduces air pollution by using an infusion system which limits the exposure to the air. The panels are also 100% reclaimable.